Participants will be required to complete three assessment tasks during this microcredential.

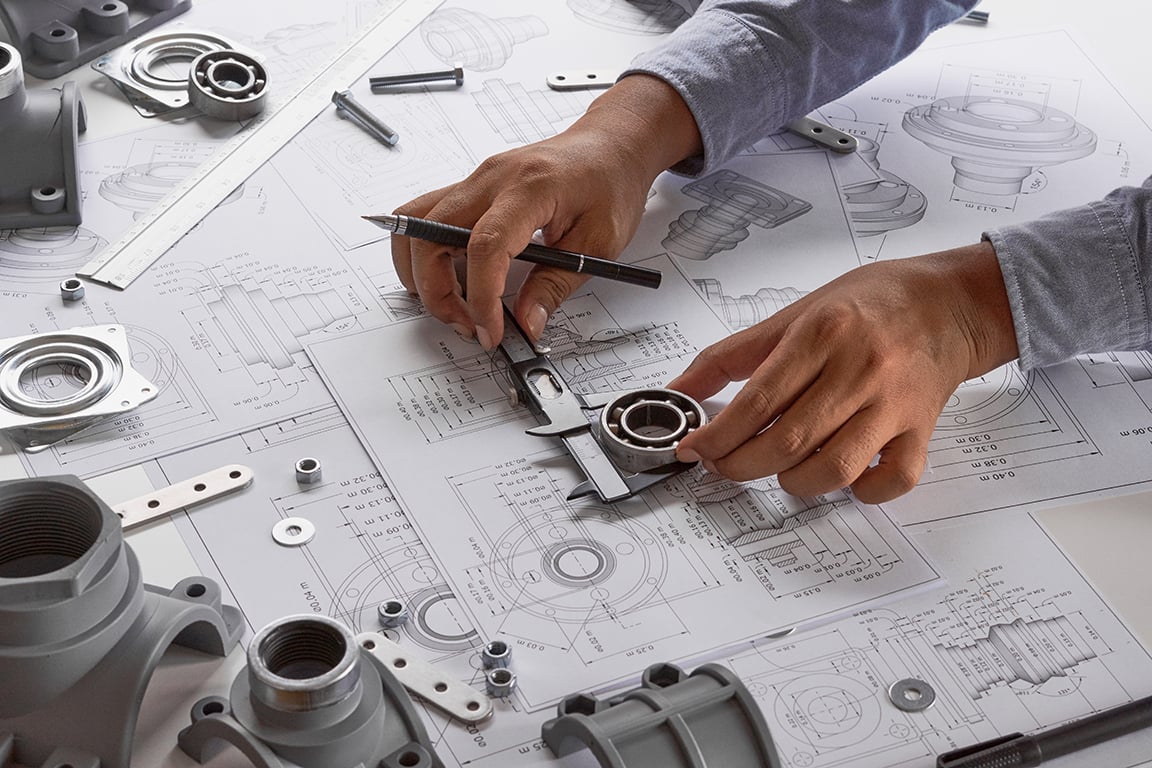

Task 1 - Participants will be required to capture and export a 3D scan and reflect on the experience with a written piece attaching the scan file. This task aims to apply understanding of camera principles in the task of 3D scanning an industrial part of moderate complexity, producing a 3D representation of the object's geometry.

Task 2 - Participants will be required to download a supplied 3D model file and rectify the errors in the file by applying mesh processing knowledge whilst saving intermediate steps. This task aims to apply understanding of the different tasks related to mesh processing in the context of 3D scanning an industrial part of moderate complexity, producing a complete 3D representation of the object's geometry.

Task 3 - Participants will be required to capture and export a 3D scan and rectify any errors by applying mesh processing knowledge. In addition, participants will load the 3D model into CAD and fit surfaces. This task aims to improve skills in 3D scanning an industrial part of moderate complexity, producing a completed 3D representation of the object's geometry in order to understand the relationship between the object surface complexity and principles of creating surfaces and parts in CAD software.