This course is structured into four modules. Each module includes self-study materials and facilitated live sessions. The following content will be covered during the course:

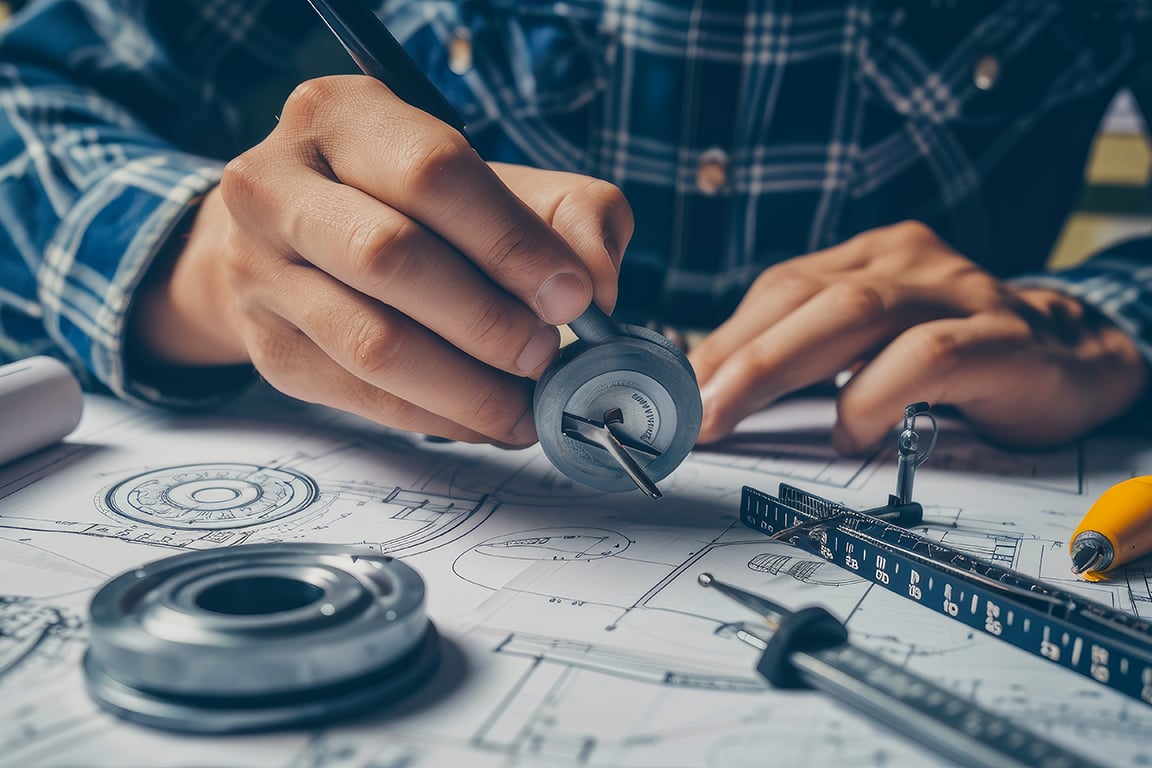

- Module 1 – Overview of Reverse Engineering Processes

Understanding of how data is analysed, collected, processed, and manipulated for various end uses.

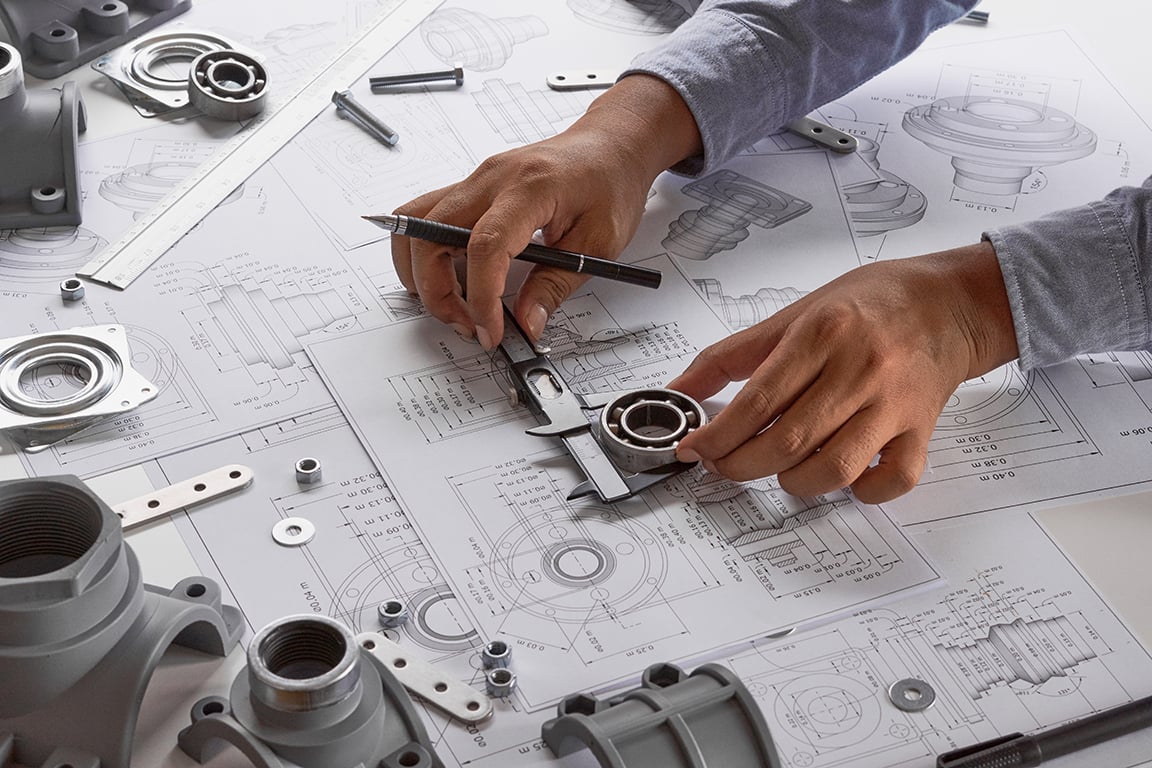

- Module 2 - Feature Selection and Data Collection for Reverse Engineering

Differentiate between critical and non-critical mechanical features, and collecting appropriate data for digital part reproduction.

- Module 3 – CAD Construction and Refinement of Parts for Reverse Engineering

Digitally constructing parts from manually measured data, and preparing CAD files for 3D printing.

- Module 4 – Evaluation and Validation of Reverse Engineered Models

Evaluate accuracy of parts and learn techniques for validating parts for modification in reverse engineering.

Participants will work with a dedicated course facilitator who will support learning and engagement online, as well as in-person. Teaching resources have been designed by a lead academic and a team of experts from the Faculty of Design, Architecture and Building.

This eight-week course includes self-paced online learning as well as on-campus workshops held in weeks 1, 4 and 7.